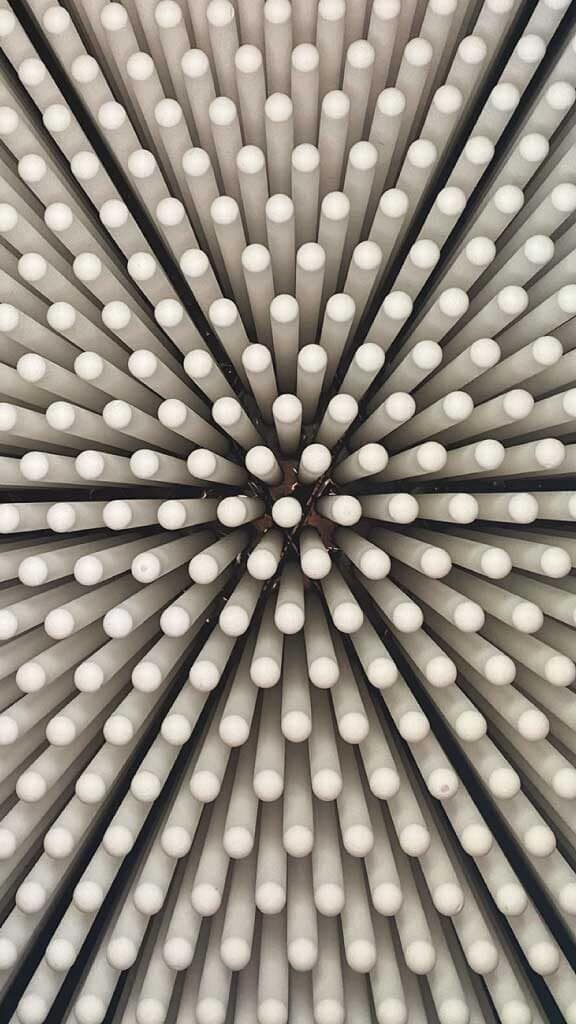

Glosfumes inhouse manufacturing facility of hot gas filter elements was developed and commercialised in 2003. Originally for the aluminium industry to solve an issue of fires happening within the filter bag housing. Sparks were being carried over in the gas stream and setting fire to the carbon collected on the fabric filters. Glosfume filters were developed using high temperature fibres and are designed to work in the same way as a traditional fabric filter but with much higher temperature capability and resistance to sparks. Since 2003, the benefits of the product mean that they have been used in a variety of applications from metal & mining to product recovery to applications such as energy-from-waste and renewable energy.

Key features of Glosfume ceramic hot gas elements include:

- A high temperature threshold of up to 1000⁰C

- Compatibility with sorbents

- Non-combustibility

- Corrosion resistance

Designing pollution control equipment around Glosfume hot gas filtration media saves CAPEX and OPEX and reduces the footprint of the installation while providing extended service life and energy savings.